3309 (Focus View) Specifications and Dimensions

Specifications

|

Parameter |

Value |

|

Linear Range |

2.0 mm (80 mils). Linear range begins at 0.38 mm (15 mils) from target and is from 0.38 to 2.41mm (15 to 95 mils). |

Incremental Scale Factor (ISF)

|

7.87 V/mm (200 mV/mil) +12.5%/–20% including interchangeability error when measured in increments of 0.25 mm (10 mils) over the 1.5 mm (60 mils) linear range |

|

Deviation from best fit straight line (DSL) |

Less than ±0.06 mm (± 2.3 mils) |

|

Frequency response |

0 to 10kHz (-3 dB) typical, with up to 100 meters (300 feet) of field wiring. |

|

Target Size |

Minimum: 8.9 mm (0.35 in) diameter Recommended minimum: 13mm (0.5 in) diameter Axial position measurements on shaft diameters smaller than 13mm (0.5 in) will generally result in a change in scale factor. Reducing the gap between the probe and target will help limit the change in scale factor. |

Shaft Diameter |

Minimum (standard X-Y probe configuration): 30 mm (1.2 in) Minimum (X-Y proximity probes offset axially by 23 mm (0.9 in)): 20 mm (0.8 in) Measurements on shaft diameters smaller than 30 mm (1.2 in) usually require close spacing of radial vibration or axial position transducers. This creates the potential for their electromagnetic emitted fields to interact with one another (cross-talk), resulting in erroneous readings. To prevent cross-talk, maintain minimum separation of m transducer tips of at least 25 mm (1.0 in) for axial position measurements or 23 mm (0.9 in) for radial vibration measurements |

|

Probe Tip Material |

Polyphenylene sulfide (PPS). |

|

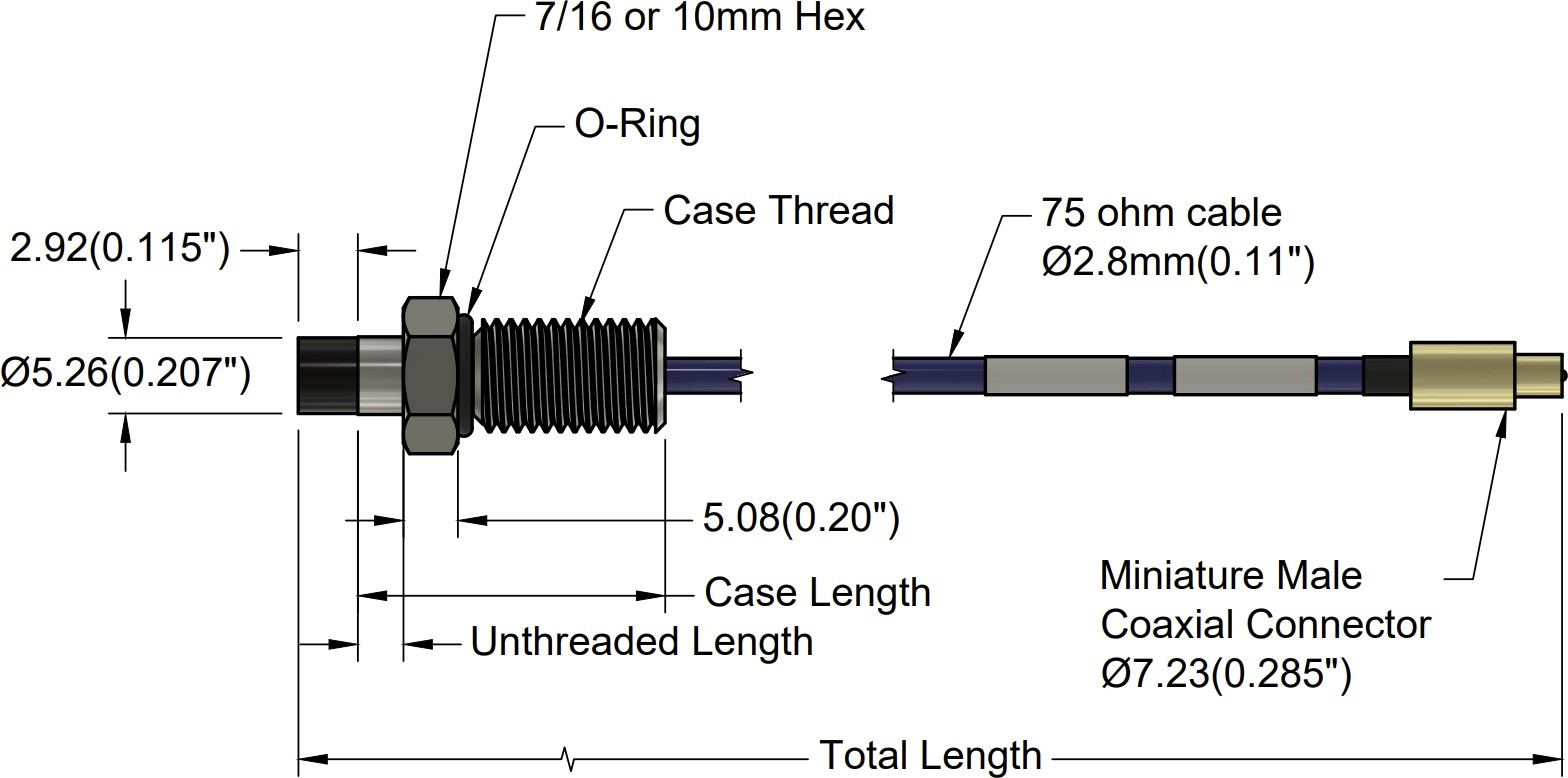

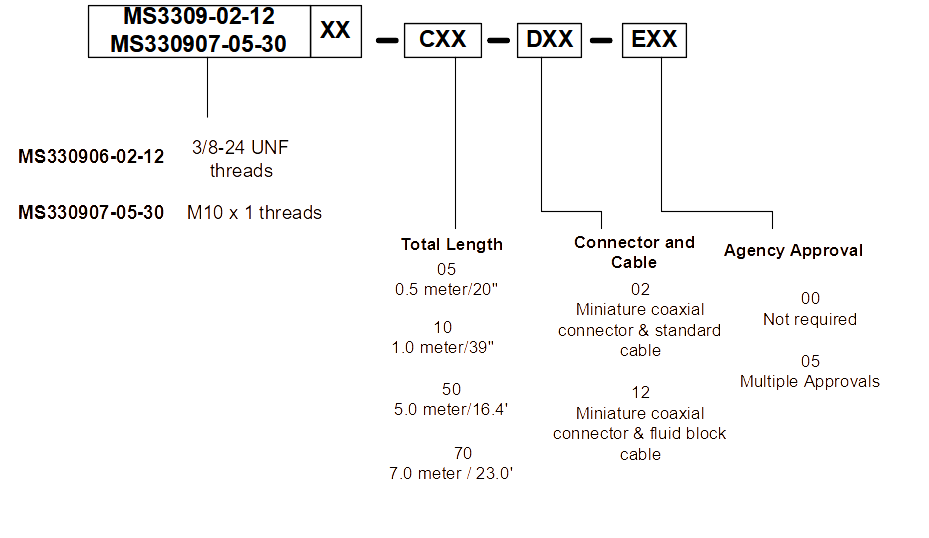

Probe Cable Specifications |

75 Ω coaxial, fluoroethylene propylene (FEP) insulated probe cable in the following total probe lengths: 0.5, 1, 5, or 7 meters. |

|

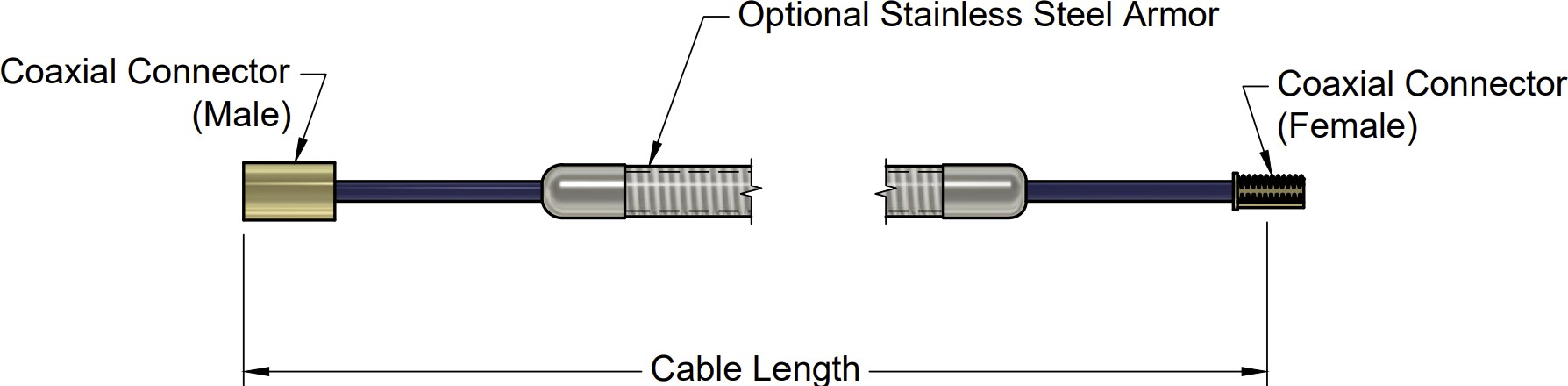

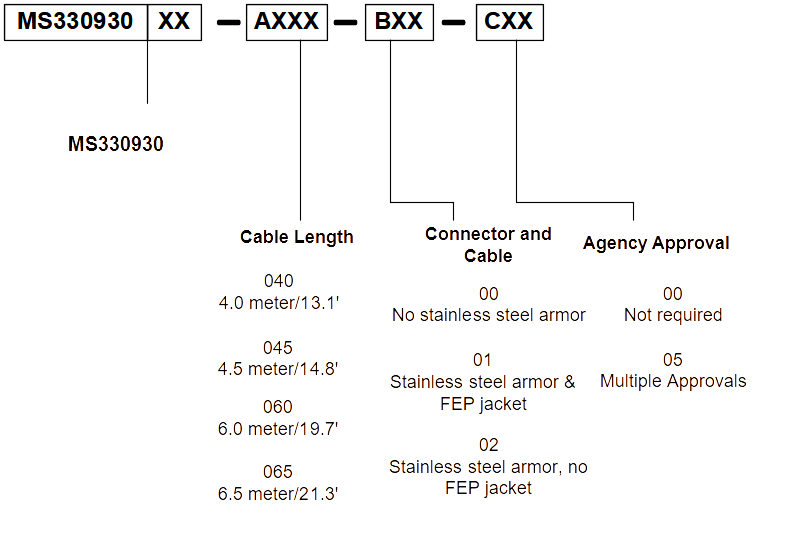

Extension Cable Material |

75 Ω coaxial, fluoroethylene propylene (FEP) insulated. |

|

System Length |

5 or 7 meters including extension cable |

|

Extension Cable Armor (optional) |

Flexible AISI 302 SST with/without FEP outer jacket |

|

Tensile Strength (maximum rated) |

220 N (50 lb) probe case to probe lead. 220 N (50 lb) at probe lead to extension cable connectors. 220 N (50 lb) probe case to stainless steel armor |

|

Connector material |

Gold-plated brass |

|

Recommended Connector Torque |

Hand tightened |

|

Maximum torque |

0.56 N• m (5 in• lb) |

|

Minimum bend Radius (with or without SS armor) |

25.4 mm (1.0 in) |

|

Probe Temperature Range Operating Temperature |

-34°C to +177°C (-30°F to +351°F) |

|

Storage Temperature |

-51°C to +177°C (-60°F to +351°F) |

|

Extension Cable Operating and Storage Temperature |

-51°C to +177°C (-60°F to +351°F) |

|

Relative Humidity |

100% condensing, non-submersible when connectors are protected |

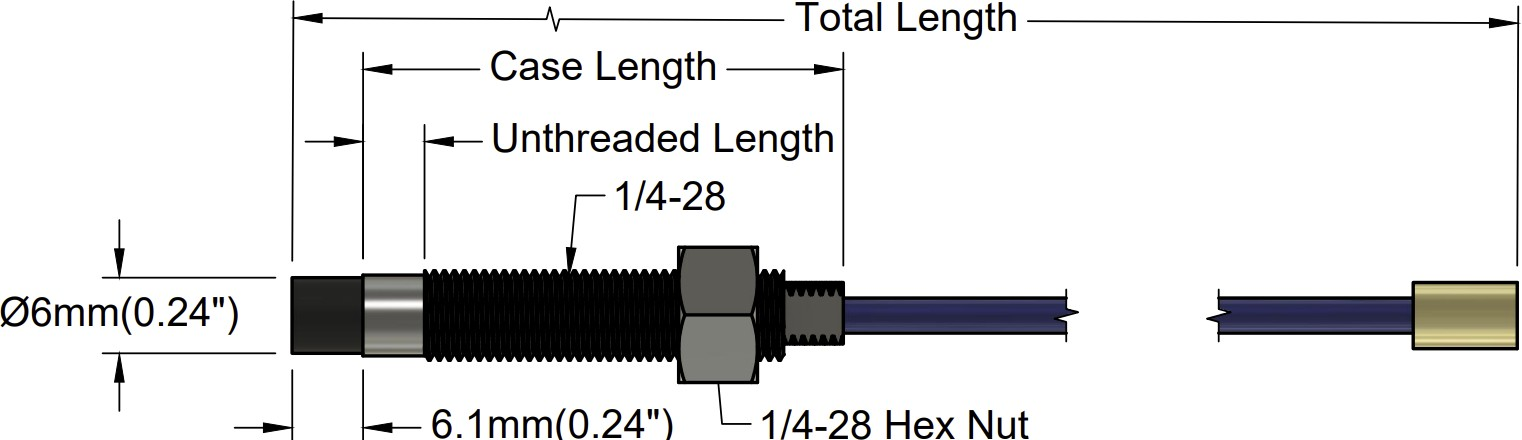

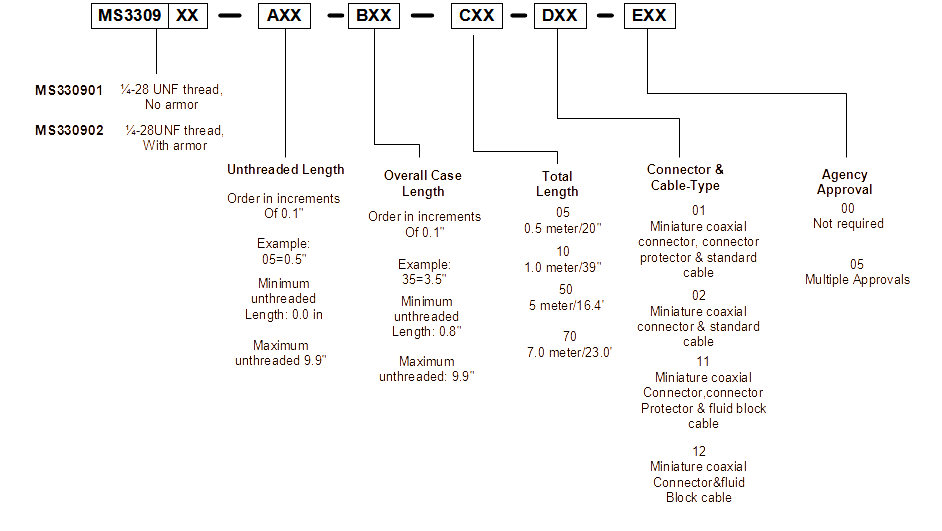

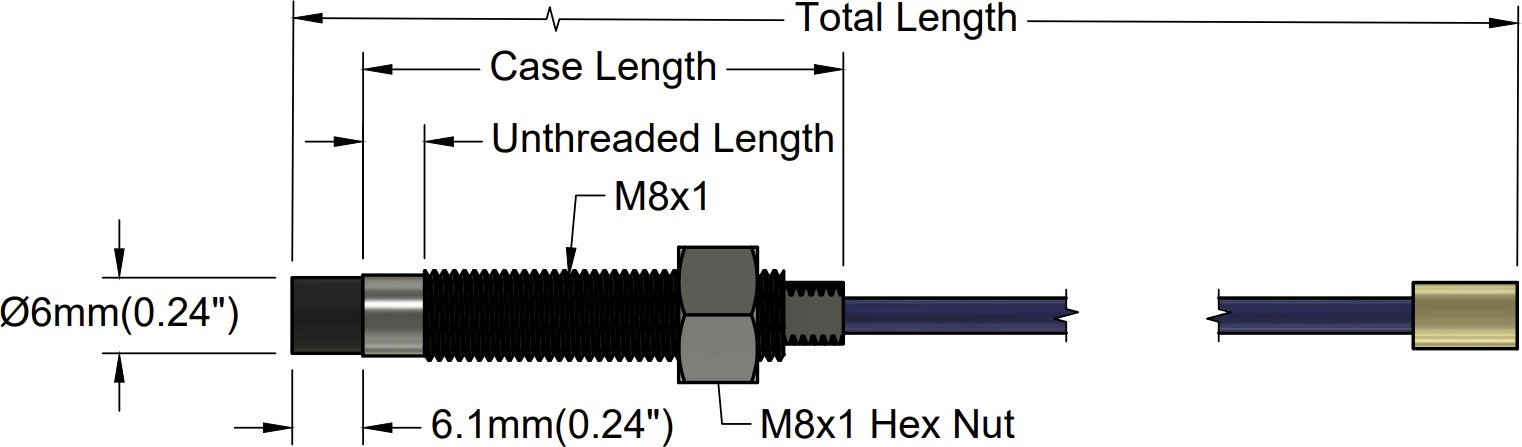

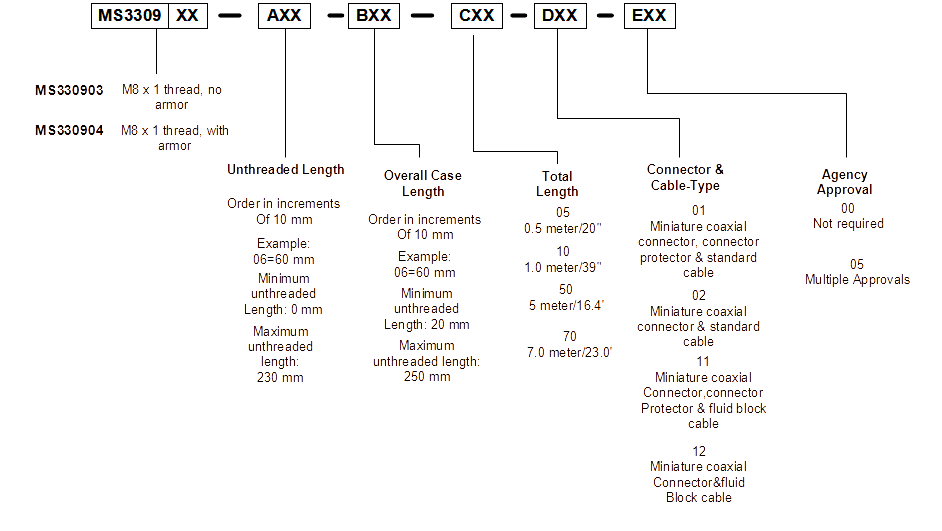

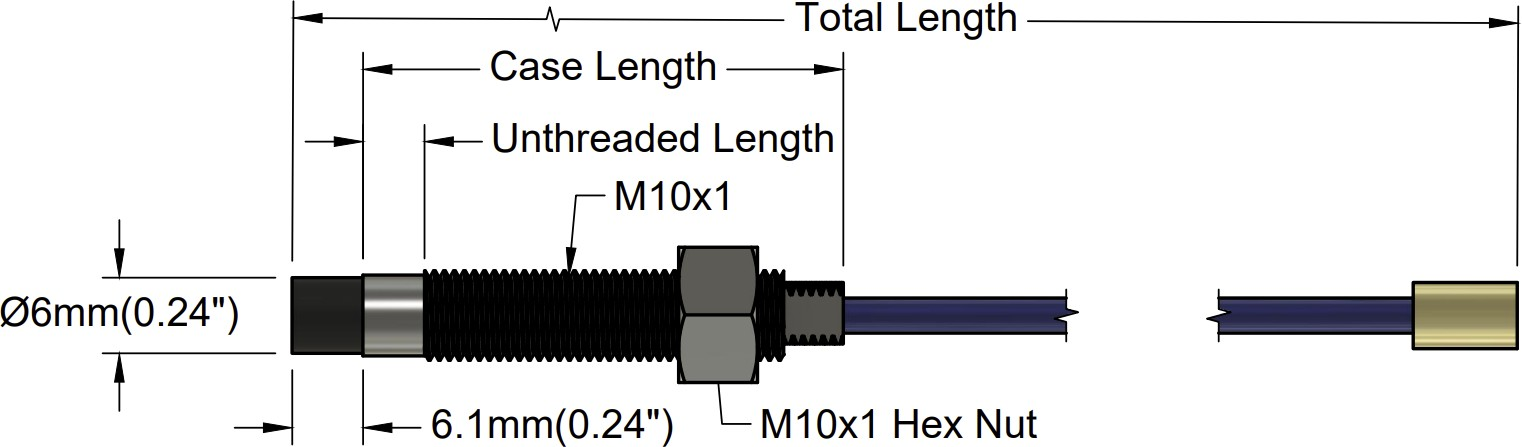

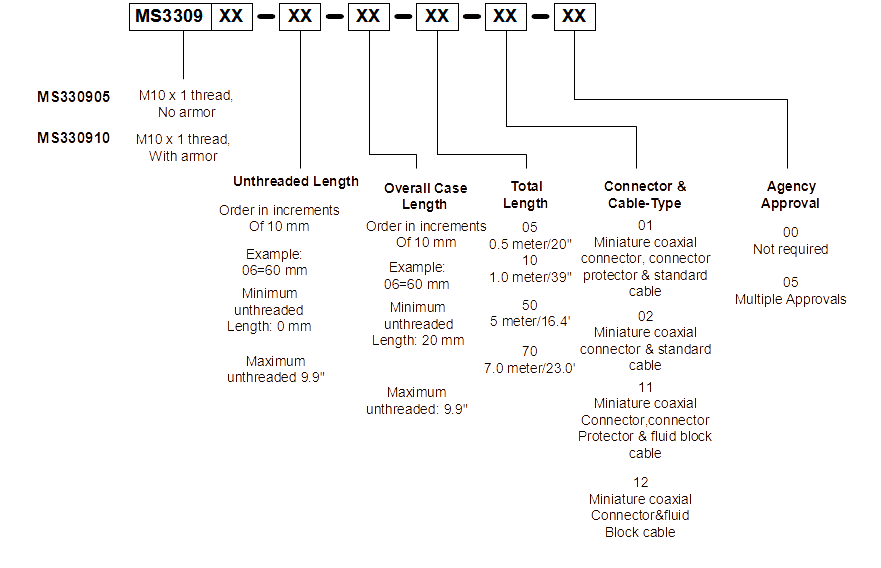

Imperial/US

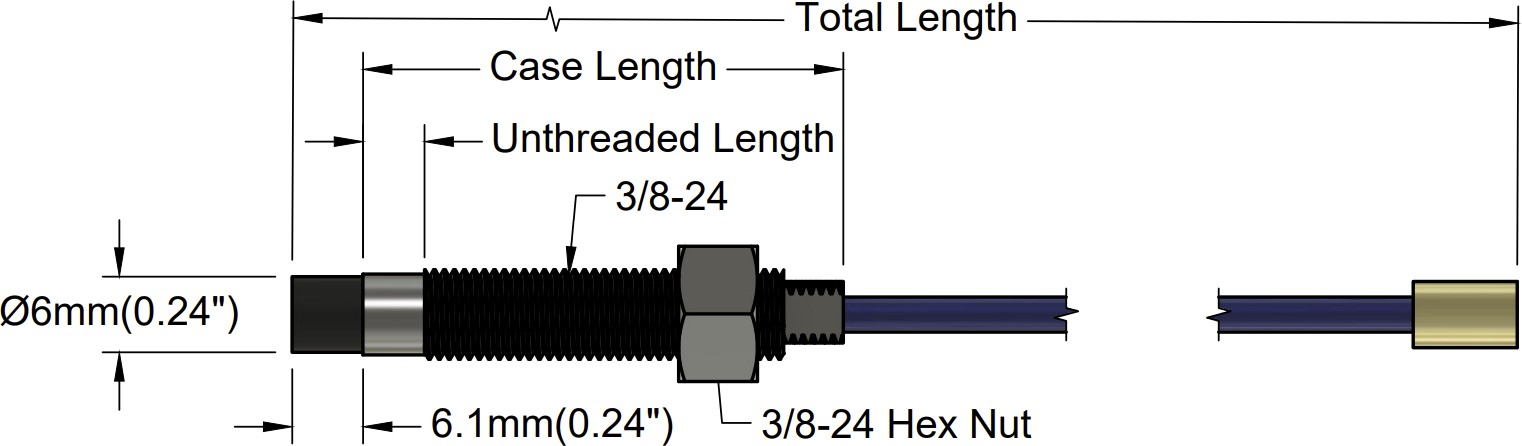

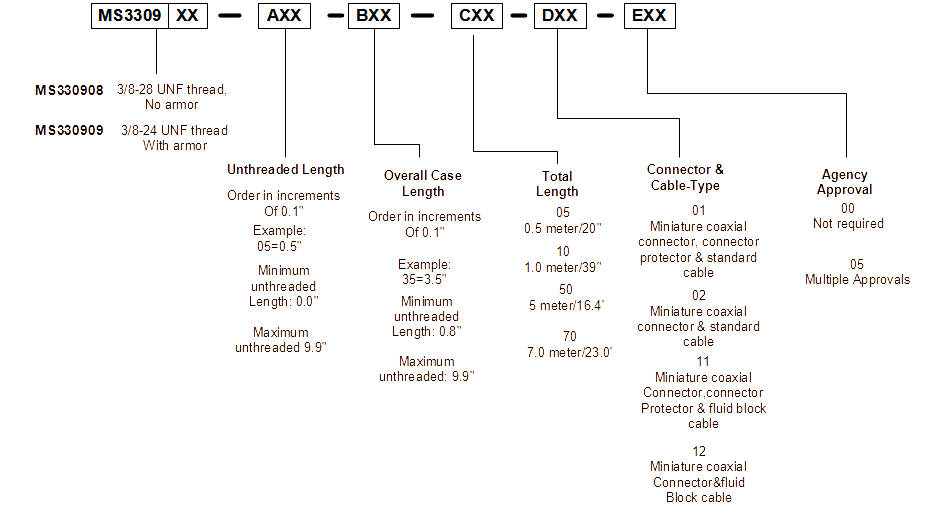

Metric

Reverse Mount - Metric or Imperial

Extension Cables

No Comments